Plumbing for

Graywater Systems

Pipe it out

Understand core drainage plumbing principles and guidelines for graywater systems.

Core Principles

Minimum Slope

Drain pipe systems need constant proper downwards slope in order to drain correctly without clogging. Quantified slope can be expressed as a percentage, a ratio (rise over run) or an angle(degrees). “2%” slope is the industry standard recommended slope for drainpipes and is the same as saying 2ft of fall over 100 ft of run, or 1/4” per ft. The pipe can NEVER slope up again and because the deeper you release the water in the landscape, the less absorbable it is by plants, (and the less effectively treated it is by the more biologically active upper soil layers) strive to “conserve fall” as much as possible (don’t slope down any more than 2% unless you have to). Preserving fall can also often make it possible for pipes to be able to exit the house through the crawlspace vents, above the foundation wall (to avoid drilling a hole in the concrete).

Plastic Drain Pipe & Fittings

Both black ABS (Acrylonitrile butadiene styrene) and white PVC DWV ((Polyvinyl chloride, Drain waste and vent )are used and each uses their own type of special glue adhesive. A cutoff saw with a grinder-type solid blade, reciprocating saw, PVC/ABS hand saw, hacksaw, or ratcheting cutters can be used to cut the pipe. Plastic fittings come in a myriad of designs and angles (i.e. 90°, 60°, 45°, 22°) that can be assembled to direct the pipe where you need it, always endeavoring to minimize turns and resistance to flow. Clean-outs (a special fitting with an access port to snake out the pipe if necessary to unclog it) should be included after every cumulative 135° of turns.

Cutting Hole openings

In wood framing requires special consideration for preserving the structural integrity of the framing. Drill the smallest hole possible for your pipe and always situate the hole in the middle of the board (away from the edge). Use a hole saw or large drill bit and use extreme caution, careful observation, and detection tools (such as a metal-detecting stud finder) to avoid hitting any existing utilities (i.e. tap water pipes, electrical wires, drainpipes, gas pipes etc.).

Gluing

Each type of pipe uses their own type of special glue adhesive. Some glues are two-step, requiring a primer first and then a glue. Make sure that the pieces are as clean as possible, put glue on both pieces, assemble them as fast as possible, and hold the joint in place briefly as it dries.

Flexible fittings

Are very useful to transition from one pipe material to another (ie. Cast Iron over to ABS) or wherever a removable connection is preferable (ie. access to a trap cleanout under a sink). The rubber fittings use metal hose clamps that are tightened down using a nut-setter or screw driver.

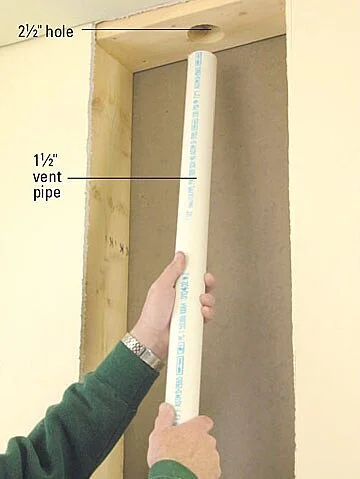

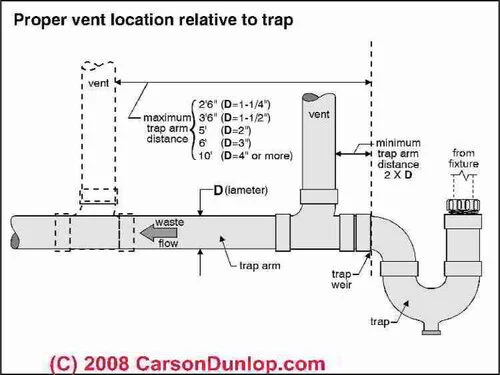

Vent pipes

As fluid flows through a drainpipe it pushes air ahead of it and sucks air behind it. Vent pipes provide an outlet and inlet for this air and prevent a vacuum from being formed that could suck the water out of the p-trap (which is meant to stay full all the time). In order for the vent to work though it must be downstream and within a certain distance from the P-trap, known as the “critical distance”. Venting for graywater pipes can be separate from toilet vents or can tie into the toilet vent 12” above the spill point of the highest fixture served by the vent. Vent pipes are easy to confuse as drain lines when one is unfamiliar with plumbing. 3-way diverter valves should always be located downstream of P-traps & Vents, otherwise they would cut off their essential function. An AAV (Air admittance valve) is used in some instances where through-the-roof vent pipes are not an option. AAV’s must be accessible (i.e. not permanently closed inside a wall) in case they fail and need to be replaced.

Pipe Hangars and Strapping

In order to keep the pipes at the correct slopes, pipe hangars and strapping are used to secure the pipe to adjacent framing in a crawlspace, at a minimum of 4’ intervals between securement.

Shower Drain Pipe Identification

The first step to installing a 3 way diverter valve is to identify the correct pipes to divert. A “p-trap” (a common component of drain plumbing systems that is full of water that prevents sewer gases from entering the building) is usually visible from within the crawlspace and helps identify the shower drain line because sinks and toilets have their p-traps located under the fixture in the house. A 1 1/2”-2” pipe size (inner diameter of pipe (“ID”)) also suggests a shower line as waste water pipes are sized by the amount of water that travels through them and toilets are always a minimum of 3”-4”. A good method of confirming you have the correct pipe is to run HOT water in the drain line until you feel the pipe heat up.

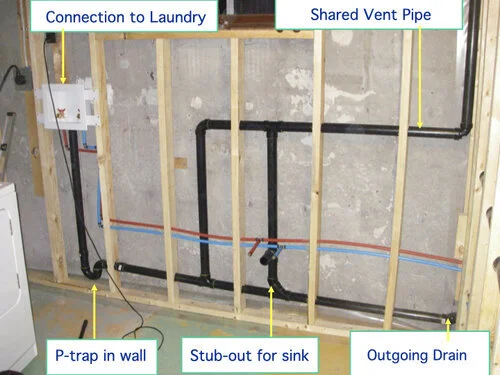

Laundry and Sinks Drain Pipe

Identification

Even though laundry graywater is often sent through an independent “Laundry-to-Landscape” system, it can also be sent through a branched drain or combined into a whole-house system. The drainpipe your laundry discharge hose empties into should be a 2” size and has a non-visible P-trap connected to it located inside the wall. Sink drain pipes can be as small as 1 1/4” or 1 1/2” and sometimes share vents with other fixtures or use an isolated vent such as an auto vent.

Sizing Drainpipes

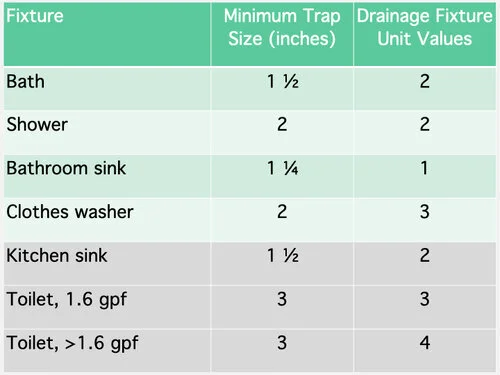

Drain line pipes are sized according to the number of “drainage fixture units” they carry. Each type of fixture (ie. shower, sink, toilet) has a different number of “units” assigned to it in the plumbing code.

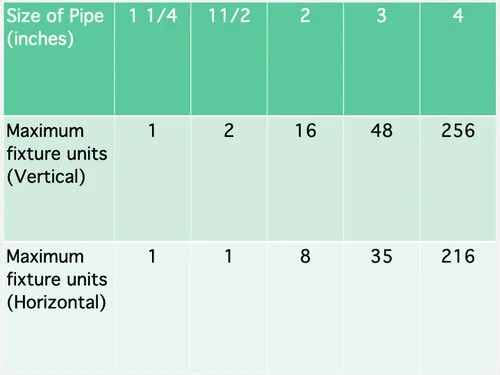

Maximum Unit Loading

Add up all the units of the fixtures you want to connect to determine what size pipe is necessary. Whether the section of pipe is vertical or horizontal also determines the amount of units it can carry. The vast majority of single family home graywater systems will be fine with a 2” pipe, and only the largest systems will need a bigger size pipe.

For example, a typical branched drain system may include a shower(2 units), a sink (1 unit), a bathtub(2) and a laundry (3) for a total of 8 units, which still fits in a 2” pipe but is the maximum units allowed in that pipe size.

Common Graywater system plumbing features

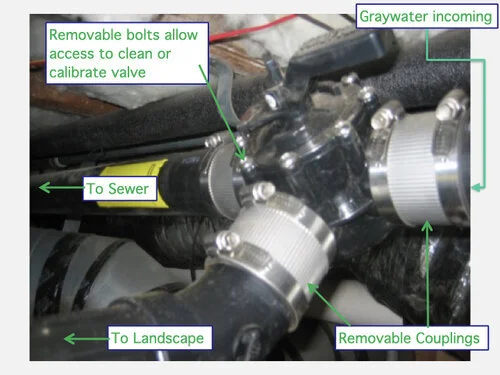

3-Way Diverter Valve

Installed in the drain line downstream of traps and vents but upstream of any connection to backwater fixtures (ie. toilet)

Uses 1.5”, 2” or larger drain pipe

An actuator may be installed on. the valve to allow remote switching from within the house (code required if the valve is not “reasonably accessible”)

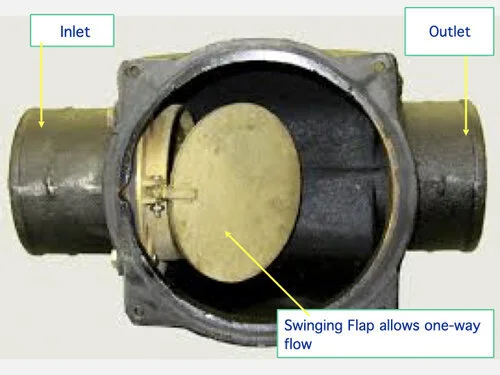

A backwater valve (aka “sewer check valve”) is typically installed on the sewer side of the 3-way valve to prevent sewer water from potentially backing up into the graywater system

Backwater Valve

AKA Sewer Check Valve is usually installed on the sewer side of the 3-way valve to prevent sewer water further downstream from backing up into the greywater system. Since the 3-way valve itself shuts off the sewer connection, the backwater valve functions only if the 3-way valve is left partially open, and this component is Not required by all jurisdictions. Must be installed in the correct orientation with flow arrows pointing downstream in order to function correctly.

Valve Actuator

If the 3-way valve is not easily accessible (e.g. tiny crawl space) you will need to install an actuator to operate it remotely from within the house. An actuator is an electrically powered motor that turns the 3-way valve, and is connected to low voltage power and a switch placed in a convenient location. The actuator itself is available from pool supply stores and is designed to fit a particular size and brand of 3-way valve. A few other components available from electrical supply stores or hardware stores are needed to complete the actuator switch:

24 Volt transformer with screw on terminals (plugs into a wall socket and reduces power from 120 Volts to 24 Volts)

A toggle-type switch

A surface mount electrical box and faceplate.

Wire nuts to make electrical connections within box

Low-Voltage wire (12 or 14 gauge)

Pumping Basin

(aka surge tank or surge basin)

Graywater is collected into a pumping basin but the system needs to be designed to empty at least every day because its prohibited to store greywater for more than 24 hours ( high amounts of nutrients and suspended solids and bacteria in graywater rapidly multiply under storage to turn into noxious septic blackwater). Other Code Requirements for pumping basins:

Watertight

Made of solid, durable material

Vented

Sealed against vermin

Access opening for cleaning

Labeled with capacity, and "GRAY WATER SYSTEM, CAUTION- UNSAFE WATER"

Passive overflow drain to the sewer (same size as inlet pipe) with a backwater valve (sewer check valve)

Unions on piping to tank

If underground, lids must withstand 300 pounds per square foot

Install on 3” thick concrete slab or compacted baserock foundation.

1/16” screens on all vents, inlets, and overflow pipes

Designed to minimize time graywater is held in tank

Designed to distribute estimated amount of graywater on a daily basis

see Code 1602.8.3 for additional details

Effluent Pump

Rated to pass 3/4” solids

Pumps are different sizes (horsepower) depending on the distance and height you have to reach

Inline float switch attached to the pump activates pump as soon as basin fills with Graywater

submersible

Vortex impeller or similar technology approved for sewage effluent

Dirty water submersible pumps are designed to pump soft solids up to 1 1/2" or more in size with little to no filtration required before the pump

Include a check valve (alllows one-way flow only) to prevent Backflow into the basin.

A course mesh hair catch filter bag recommended be installed at the inlet into the basin, designed such that even after clogging it does not impede the passage of graywater into the basin.

Include Unions ( a plumbing coupling designed to be easily removable)to allow for easy removal and maintenance of the pump

Power for pump typically supplied by an existing plug-in 120 V GFCI outlet (cutting the plug off the end of the pump cord (for hard wiring) will void the pump warranty)

Electricity use of a 660 Watt pump (running for 1/2 hour per day in a typical 4-person household), would be an actual use of 450 Watts during operation, for a total daily power usage of 0.25 kilowatt hours which represents 0.6% of the average home power consumption.

Self-Cleaning Filters

(Vary widely according to design)

Graywater is pumped through an automated self cleaning “Disc filter” containing a stack of discs each with a series of microscopic grooves whose dimension determines the effective mesh size of the filter, ranging from 40 to 600 mesh. Graywater is filtered as it flows through the disc grooves, which contain up 100x the surface area of a screen filter, but nonetheless clog readily and thus require a self-cleaning mechanism that shifts from normal filtration flow to backwash by reversing flow direction. Triggering the backwash cycle can be done through the use of pressure sensors upstream and downstream of the filter that measure the pressure differential (pressure loss) across the filter (Which increases as the filter becomes clogged), or through the use of timers that flush the filter on a regular interval. Filter backwash water is usually provided by a pressurized feed from municipal water, with cross connection prevention provided by a code-compliant, Reduced Pressure Principal-type double-check valve Backflow prevention device.

Avoiding manually cleaned filters

High amounts of dissolved solids, nutrients and associated bacteria in graywater rapidly clog filters such that relying on manually cleaning a filter is NEVER recommended. Abandonment of greywater systems due to filter & maintenance failure is the inevitable situation occurring with manually cleaned filter systems. All successful filter systems are automatically self-cleaning and regardless tend to require the most troubleshooting of any part of the system.

Sub-Surface Drip

After filtration graywater is distributed to the landscape via a 1” supply line(PVC or PE) connected to 1/2” dripplerlines with built-in “in-line” drip emitters. High amounts of suspended solids (i.e.dissolved detergents, dirt) and bacteria in unfiltered graywater quickly clog traditional drip emitters so use emitters specially designed to resist root intrusion and irrigate with waste water. Dripperlines are laid on or under the soil surface, covered by 2” of mulch (aka sub-mulch) or soil (aka sub-soil), with the spacing between lines determined by the soil type and plant material.

Very low flow dripper zones may release graywater slower than it is being generated, causing the water level in the pumping basin to build up and overflow to the sewer. While very high flow dripper zones may require more water to pressurize the dripperline than the volume of graywater normally generated in a typical house at any time.

Optimal zone size generally ranges from 500 to 1000 square feet and should be divided according to geography of the site and water requirements of plants.

Designing and Calculating Drip Zone Flows

Greywater drip zones are usually designed to irrigate at approximately the maximum flow rate that graywater is being produced into basin, which avoids ever losing water through over flow. Theoretically if multiple fixtures in a whole house system were being used at the same time (i.e. 2 people showering @ 2.5 gpm + Laundry machine (2.5)and sink(2.5)) then producing 10 gpm is a good rough estimate of the maximum theoretical rate of production. To determine the flow rate of a drip zone, add up the total linear feet of dripper line and multiply by the flow rate of the drip emitter which is measured in gallons per hour, and divide by 60 (minutes in a hour) to get the flow rate in gallons per minute: (i.e. 300 ft x 2 gph emitters =600 gph/60 = 10 gpm.

Make-up water

refers to the supplementary water (usually freshwater) that is distributed through the greywater system to cover any irrigation requirement not fulfilled by the amount of greywater produced. Make-up water can be added to the pumping basin through an “air gap” situation or can is allowed to be directly connected to the graywater system (allowed in some jurisdictions) if protected by an approved RPZ Backflow Prevention Device.

Backflow Prevention Device

Backflow prevention devices ensure water quality by preventing contamination of the potable (drinking) water supply due to back-pressure or back-siphonage of graywater into the municipal system. Local regulations vary as to acceptable backflow standards but generally speaking the Reduced pressure (RP) backflow device ( RP valve) is the most reliable backflow prevention device and can protect against both back- pressure and back-siphonage. Above ground installation is required with concrete stabilization and a minimum 12-inch gap between the relief valve and finished grade to allow the RP to discharge water when a back-siphon situation occurs. Backflow preventer devices are legally required to be inspected annually by a certified backflow inspector.